How Does Ept Continuous Hinge Work

Continuous Hinges

Introduction

This article takes an in depth look at continuous hinges.

You will learn more about topics such as:

- What is a Continuous Hinge

- Uses for Continuous Hinges

- Types of Continuous Hinges

- The Benefits of Continuous Hinges

- And much more…

Chapter One – What is a Continuous Hinge?

A continuous hinge is an extended single unit hinge that spans the full length of a door, cabinet, lid, or enclosure entrance. They are made of lightweight metals and can be cut to fit the size of any opening. Much like smaller hinges, continuous hinges have pre-drilled holes for easy installation though wings without holes are available.

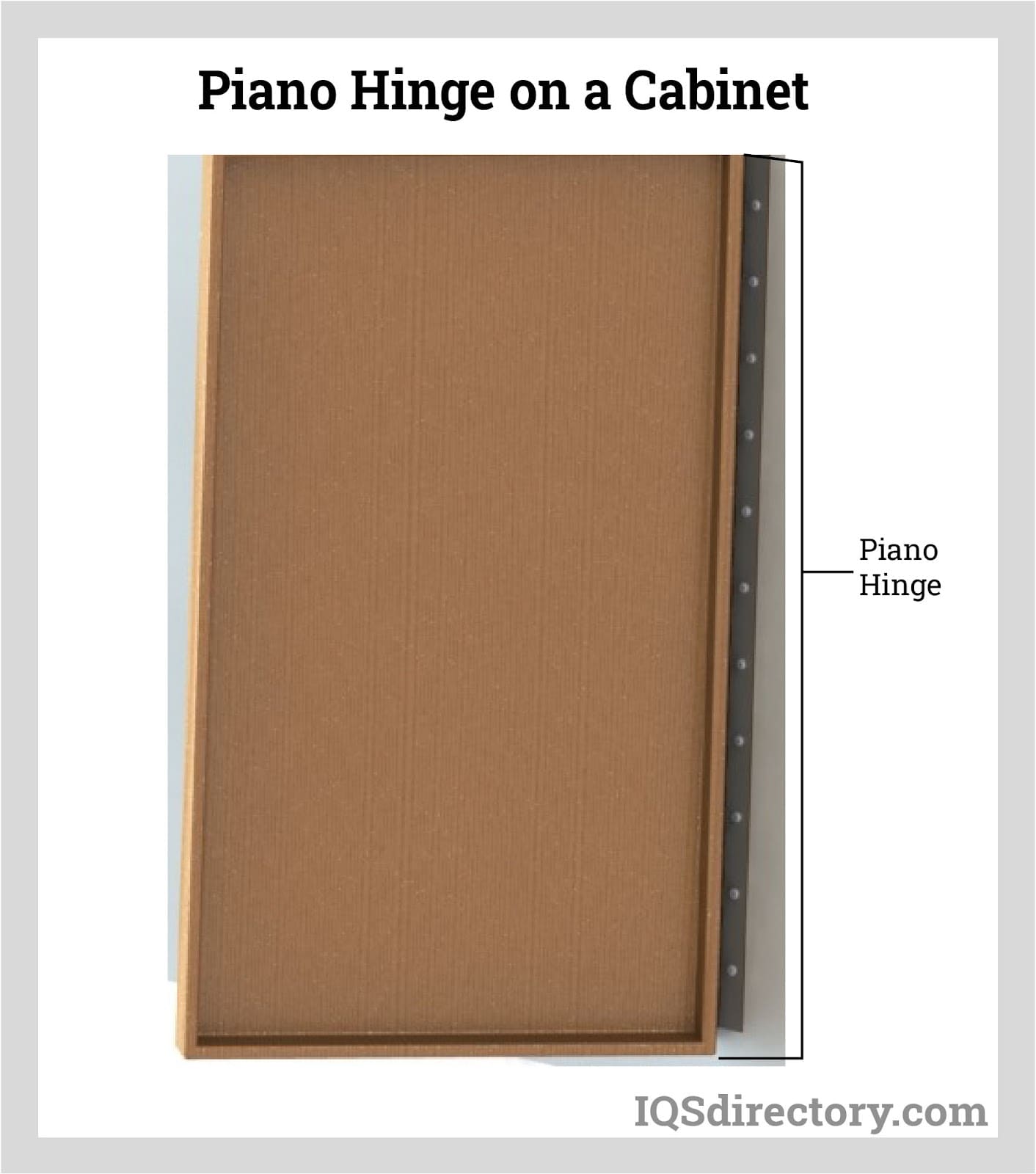

The original continuous hinges were made to hold the lid of grand pianos, which gave the hinges the name "piano hinges." As other uses for piano hinges were discovered, the more general name of continuous hinge became popular.

Over the years, piano hinges have changed and developed into continuous hinges for use in a wide range of applications and multiple configurations. They are manufactured in lengths of six, seven, and eight feet and come in different thicknesses, pin diameters, widths, and finishes. The durability of continuous hinges makes them perfect for applications that experience extensive use and intense wear, such as doors to prison cells and fire doors for fire exits.

Chapter Two – The Piano Hinge

During the history of the development of the piano from the monochord to the clavichord to the harpsichord and on to the pianoforte, there have been various inventions and innovations that have been added to the instrument to create its modern day appearance. In the process, piano inventors struggled to find a method for supporting the cover or lid that protects the major components of the instrument.

For the earliest models of the piano, having a cover was not an issue. With the development of the harpsichord, it became necessary to develop a method for opening and closing the lid since lifting it for performances was impractical. In their search for a method to resolve the problem, piano innovators came up with the idea of a hinge to hold the lid such that the workings of the sound board and strings could be heard.

Craftsmen and designers were asked to produce a hinge capable of spanning the full length of the lid and supporting it without interfering, suppressing, or diminishing the resonance and sound of the instrument. In addition, the hinge had to be lightweight and adaptable but strong enough to support the heavy open lid.

The initial piano hinges were precision designed, fitted, and made to specifically conform to the dimensions of the long edge of the piano lid with adjacent or staggered holes. Hinge craftsmen completed the work by hand, which included shaping the metal to include the barrel for the insertion of the pin, which was a long continuous solid metal dowel.

As the use of piano hinges became widespread and popular and moved from their exclusive use for piano lids, manufacturers had to develop methods for producing them faster and more economically. This led to a process that fed two pieces of steel continuously through a machine. As the steel pieces progressed through the continuous process, the long pin or dowel was positioned between the pieces of metal. The knuckles were formed over the pin to unite the pieces of steel and produce the piano hinge.This particular process is still used by manufacturers today.

The fabrication of piano hinges happens as quickly and rapidly as material is fed into the back of the forming machine. The continuous process allows for the placement of various shapes of holes and the cutting of the hinges into different lengths. The measurement of a piano hinge is determined by its open width across both of the leaves or wings. It is further defined by the diameter of the pin that runs the length of the hinge and the thickness of the leaves.

Chapter Three – Continuous Hinges

The original piano hinge has become a necessary part for securing doors and openings on cabinets and enclosures. Since its beginnings as a necessary part of pianos, its use has expanded into a wide range of applications, which has caused the original piano hinge to take on forms that are heavier, more durable, and diversified. All of the many functions of piano hinges have led to it having three names.

Though the term piano hinge harkens back to the development of the first hinge for piano lids, it is still used today by hinge manufacturers to distinguish piano hinges from barrel, butt, butterfly, flush, knife, mortise, offset, pivot, soft close, spring, and strap hinges. One of the names that has stuck with piano hinges is continuous, which is a description of the process used to produce piano hinges.

Though the name continuous hinge is used interchangeably with piano hinge, some producers give obeisance to the original long continuous hinge by referring to it as a piano continuous hinge for clarification purposes.

The original and first piano hinge included two wings with curled knuckles between the wings that were connected by a pin or long dowel. This particular configuration is still commonly used today but is only one of the many types of piano continuous hinges. The sizes, varieties, and types of continuous hinges is endless and includes ones that are made from several different types of materials. In many ways, this is where the break occurs between the old piano hinge and continuous hinges.

When craftsmen were carefully shaping and developing the original piano hinge, they had crude metals to use. Today, the types of materials used to produce continuous hinges still includes the original metals but has expanded into more technical and unique ones, which include plastics and fabrics. The modern materials used today for piano or continuous hinges did not exist at the time of the introduction of the piano hinge and are the breaking point between continuous hinges and traditional piano hinges.

Chapter Four – Types of Continuous Hinges

Hinges come in a wide array of sizes, types, and designs, with ones for small jewelry boxes to ones that hold the doors to vaults. Each of the many types are designed to fulfill a specific purpose and meet the needs of an application with different lengths, styles, sizes, strengths, and ones for aesthetic purposes. In the varied styles of hinges, continuous hinges stand out due to their length and uncommon usage.

Continuous hinges are made from a variety of materials that include metals such as steel, stainless steel, aluminum, nickel, brass, plastics, and fiber. The many uses of continuous hinges include grades classified for commercial, residential, heavy duty, military, and marine use.

Continuous Hinge Types

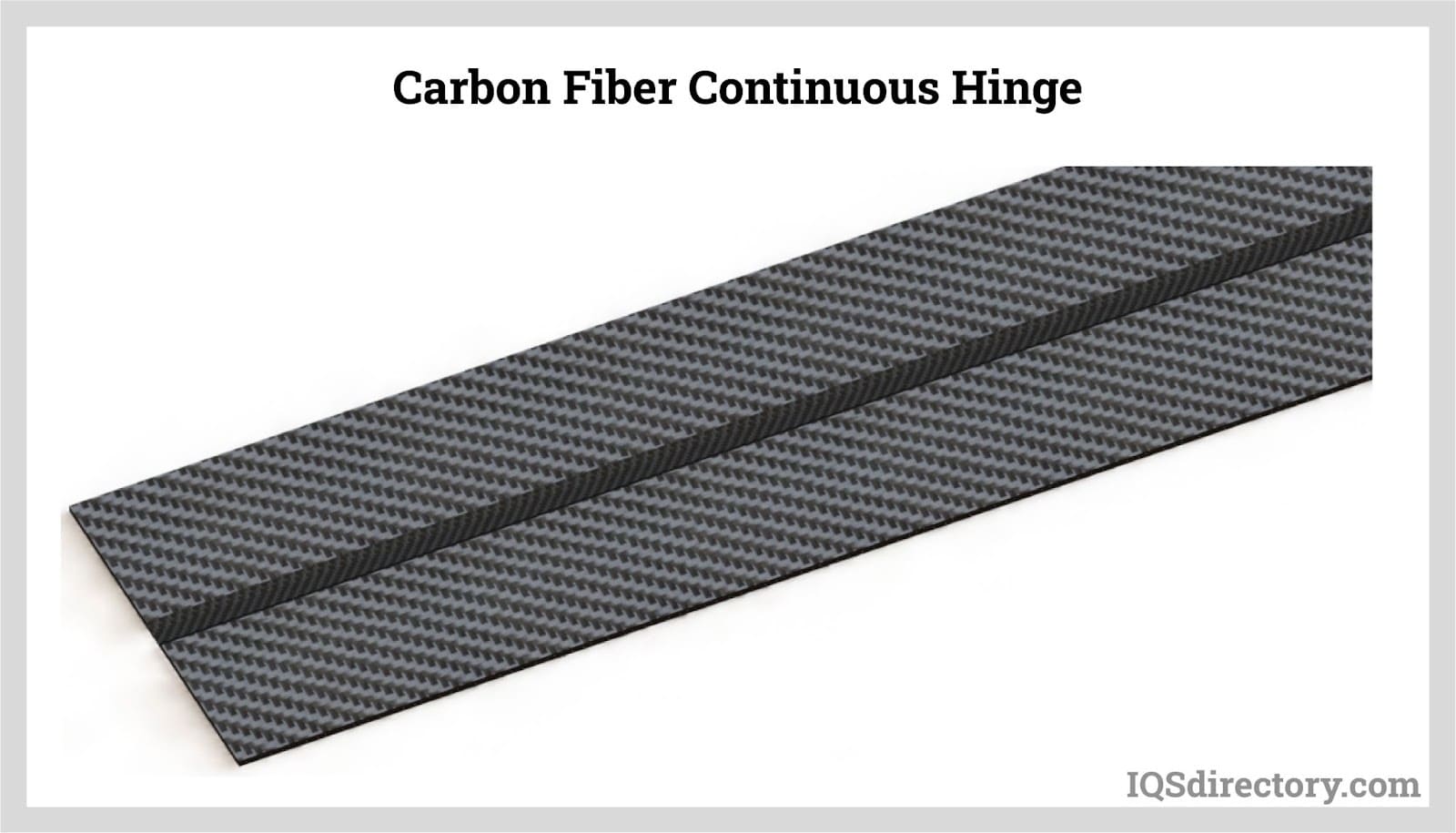

Carbon-Kevlar Continuous Hinges

Carbon-Kevlar continuous hinges are made from carbon fiber with a flexible gap between the wings. Unlike gear, pin and barrel, and pin and barrel plastic hinges, carbon-Kevlar continuous hinges are one unit with a flexible space between the wings that serves the same function as a pin in a barrel. The flex unit is woven Kevlar that has urethane injected into it.

As with all continuous hinges, carbon-Kevlar continuous hinges come in various sizes and come as heavy duty hinges with a double Kevlar layer.

Friction Continuous Hinges

Friction continuous hinges, also known as torque hinges, use internal friction to be held in position. When a door or lid is opened, the hinge keeps the door of the application in a set position, preventing it from accidentally closing. Friction continuous hinges are designed in accordance with the axial and radial tensile load strength necessary to support a lid or door and hold it in position.

As can be seen in the image below, the knuckles fit closely together.

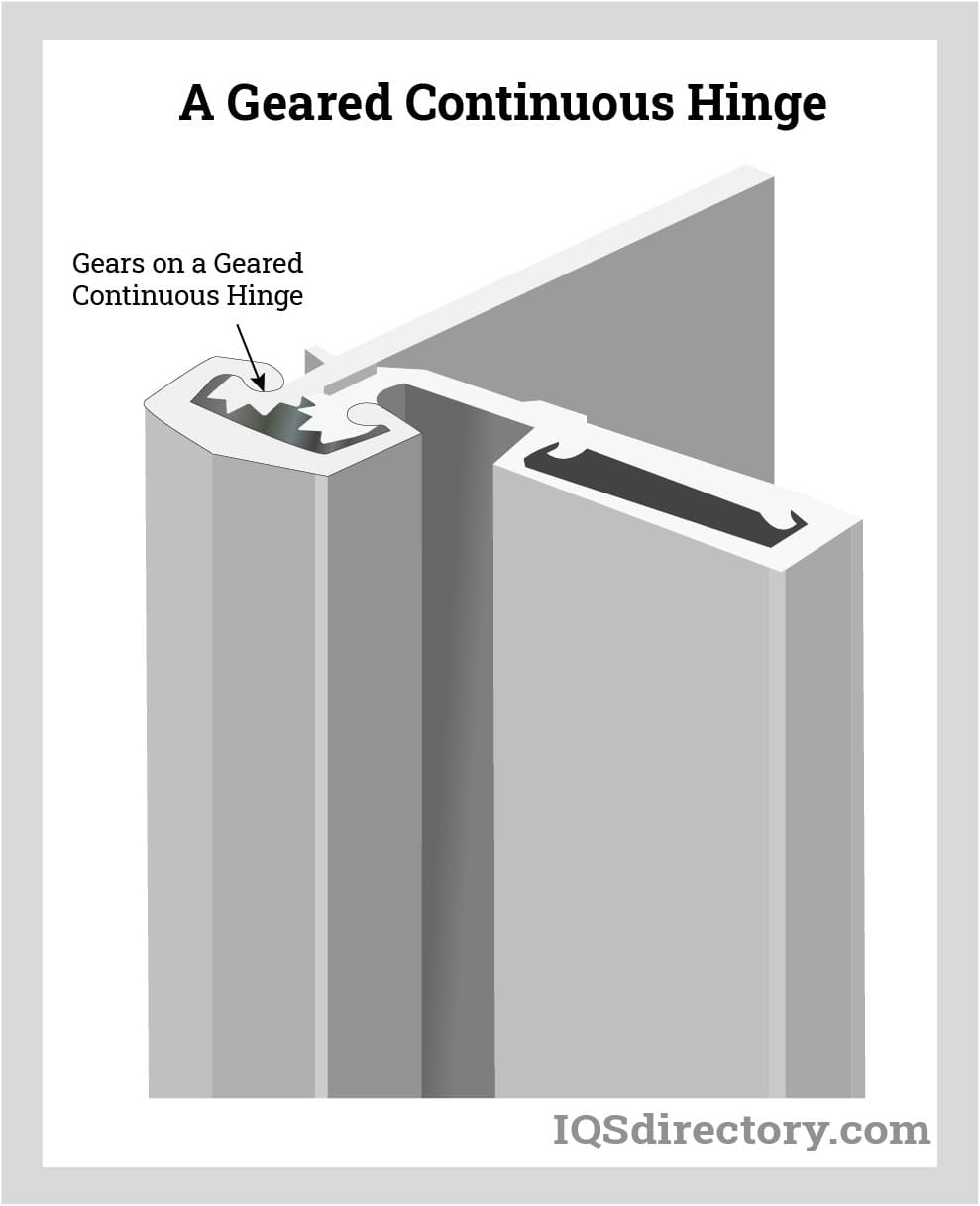

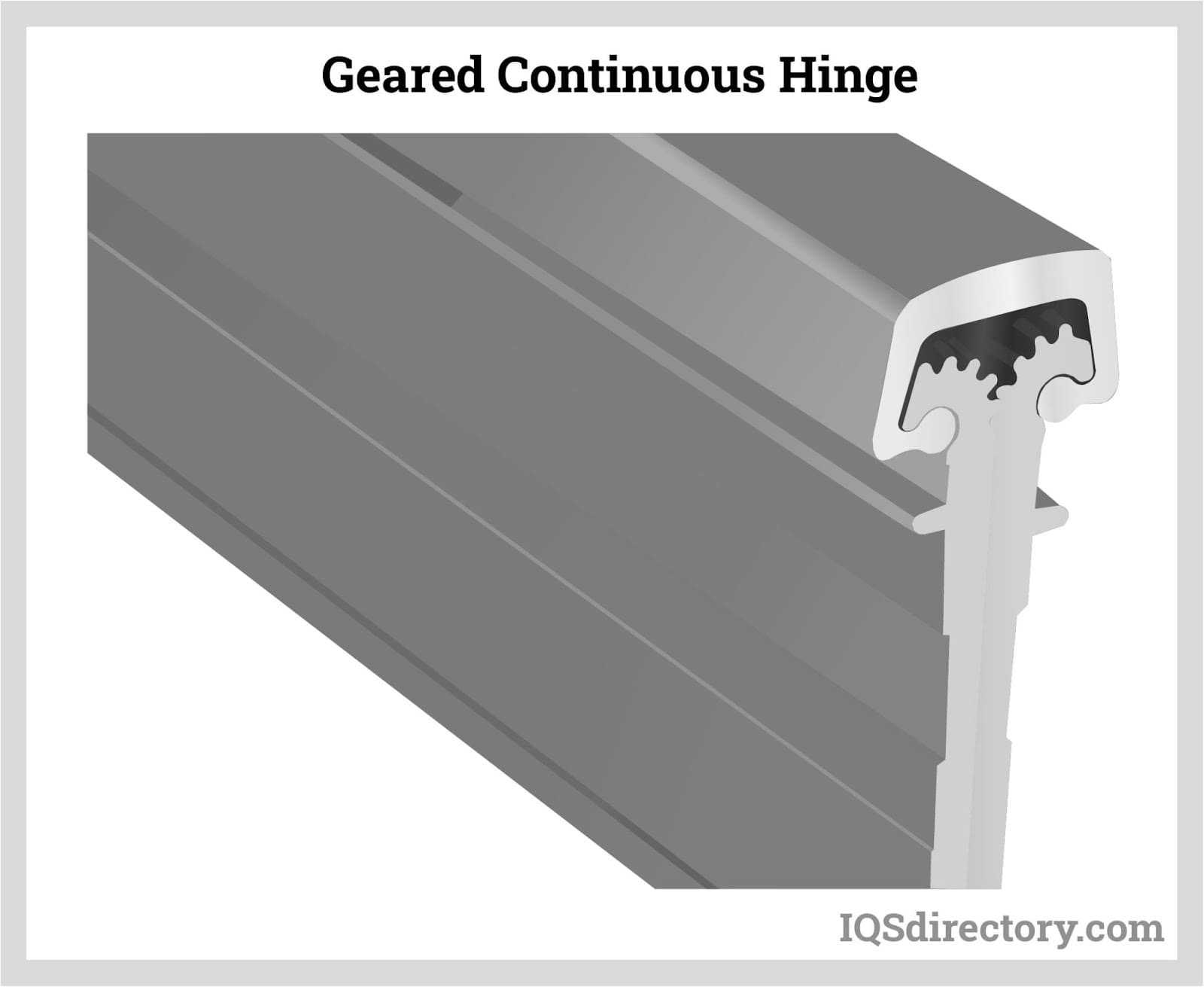

Geared Continuous Hinges

Geared continuous hinges are designed for high traffic areas such as stores, businesses, or offices. They have geared teeth that fit under a cap with gears running the full length of the hinge. Due to the types of applications where they are used, geared teeth continuous hinges are made of highly resilient, durable, and heavy duty materials.

There are many kinds of geared teeth continuous hinges, with each having the common feature of the gears being placed in a concealed leaf similar to a channel.

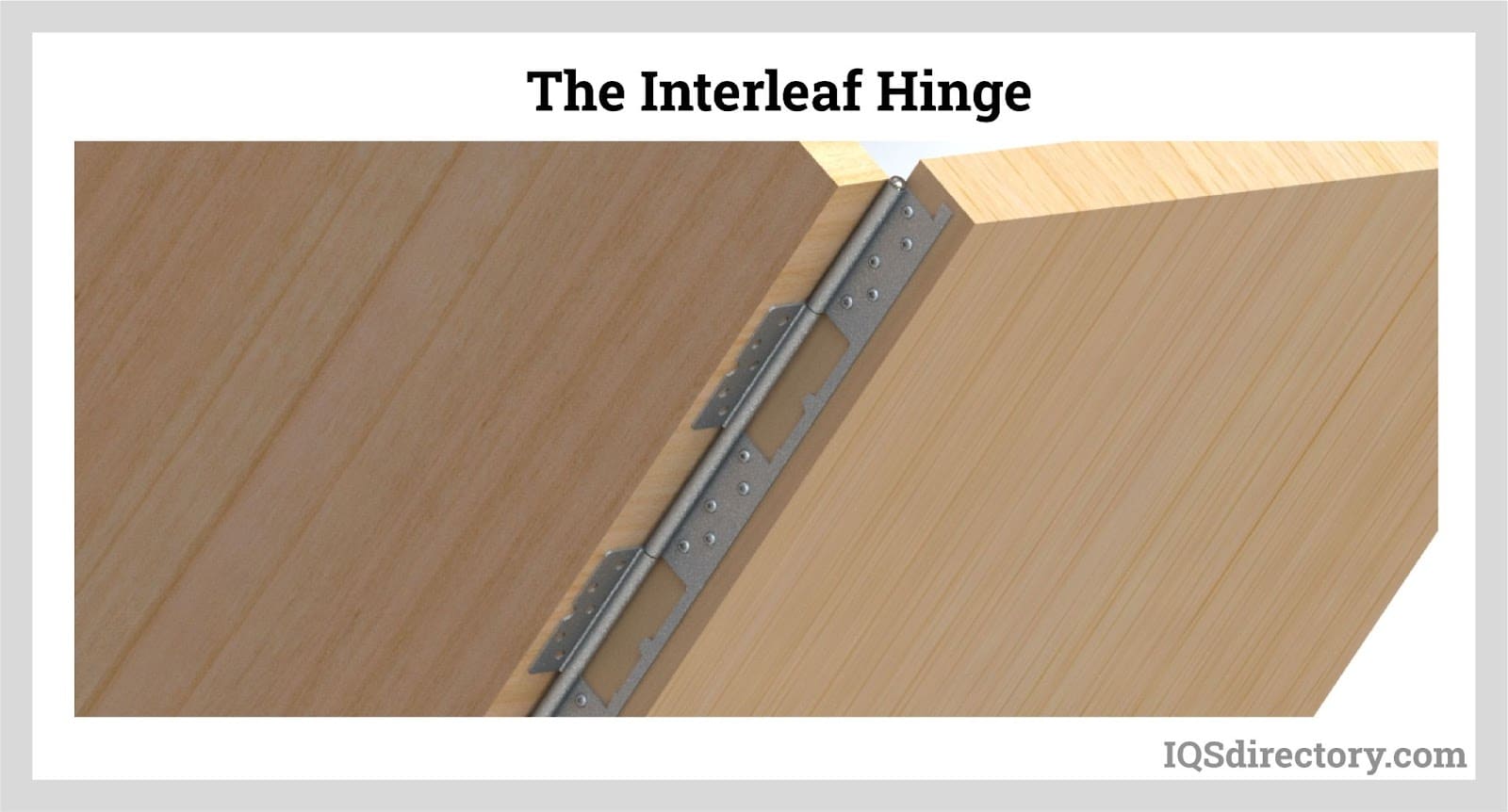

Interleaf Continuous Hinges

The interleaf continuous hinge drastically limits the clearance gap found in other continuous hinges by its unique design. The normal clearance gap for most continuous hinges is 12 mm. The interleaf continuous hinge cuts the clearance gap to 3 mm. The unique configuration of the interleaf continuous hinge significantly changes the amount of time necessary for hinge installation.

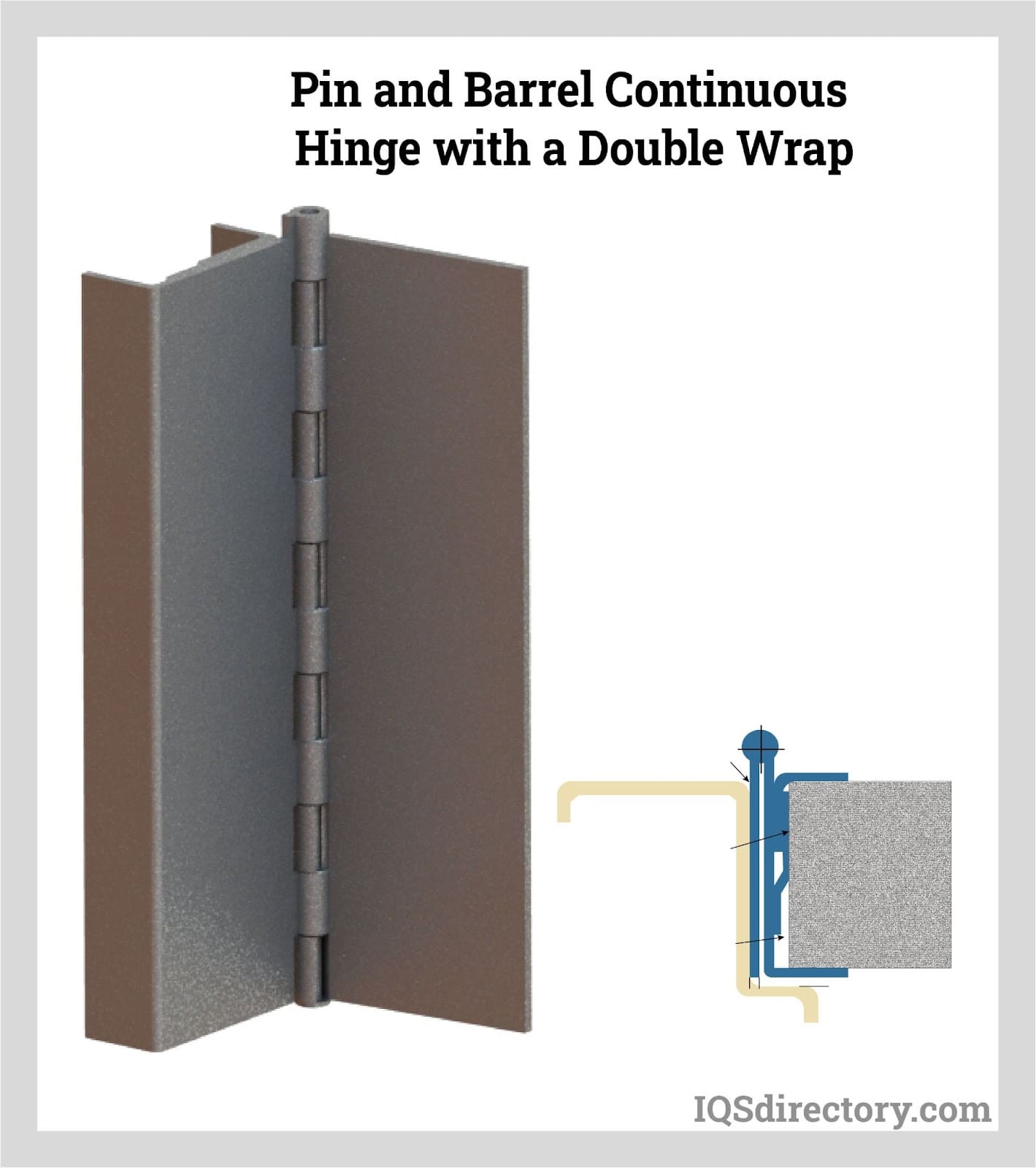

Pin and Barrel Continuous Hinges

Pin and barrel continuous hinges have a long barrel that runs the full length of the hinge with a pin inserted in the barrel. They are like traditional three to five inch door hinges but with a far longer barrel and pin, up to ten feet. Some designs of pin and barrel continuous hinges have edge protectors that wrap around the edge of the door to add greater strength and are capable of carrying additional weight. The wrap can be single or double, depending on the needs of the customer.

Much like geared continuous hinges, pin and barrel continuous hinges are manufactured to carry heavier loads.

Plastic Hinges

Plastic hinges are made from several types of plastic and are a lightweight and low cost alternative for metal hinges. They are mainly used as weatherproof hinges due to their being rust resistant and watertight. Plastic hinges are exceptionally durable and come in a variety of colors to fit the needs of an application. As with all continuous hinges, plastic hinges are available in lengths of three to ten feet.

One of the main benefits of plastic hinges is their smooth, silent, and effortless operation.

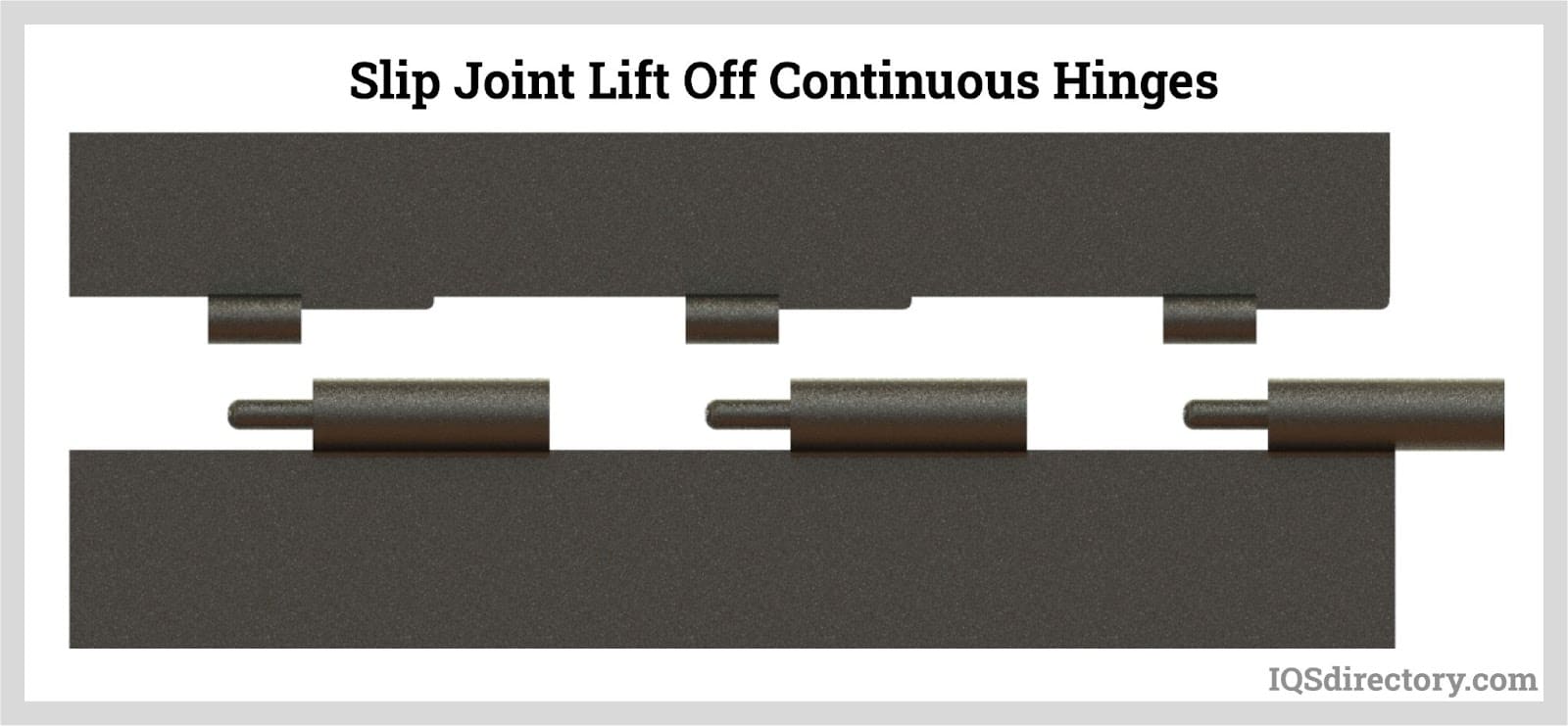

Slip Joint Lift Off Hinges

Slip joint lift off continuous hinges have a pin attached to one leaf or wing that slides into a female leaf or wing with a barrel. There are several names for slip joint lift off hinges, such as take apart or loose joint hinges. Slip joint lift off continuous hinges make it easy to detach a door or lid by simply lifting it and disconnecting the male and female joints.

The many uses for slip joint lift off continuous hinges includes lids or doors used frequently and need to be removed. The configuration of slip joint lift off continuous hinges can be left hand, right hand, or reversible such that the door can be used in either direction.

Slip-On Continuous Hinges

Slip-on continuous hinges are a unique form of hinge that can be attached to a door without drilling holes. They are composed of two channels formed from plastic that are connected by a flexible plastic joint. They attach to a door and frame by having the channels stretched over the edge of the door and frame.

Tight Clearance Hinges

Tight clearance continuous hinges can be pin and barrel or gear type hinges that touch when a door is closed to form a tight secure seal. Pin and barrel tight clearance continuous hinges are made of metal with knuckles that fit closely together. Tight clearance continuous hinges are used for enclosures that require a tight seal against the elements or for security reasons.

Chapter Five – Uses for Continuous Hinges

Of the many types of hinges, continuous hinges stand out due to their length since they run the length of the lid or door that they support. Unlike the traditional three, four, or five inch hinge found in every home, business, and store, continuous hinges can be six to eight feet long but have a similar structure to that of their smaller cousins.

Depending on the location, most doors, lids, cabinets, and openings have two to four small hinges to support them, which allows them to easily swing open. In more stressful and demanding conditions, continuous hinges are a more durable and stronger alternative to multiple hinges.

Continuous Hinge Uses

Piano Lids

The original name of continuous hinges was piano hinges, which is a name that many manufacturers still use. The piano has taken many hundreds of years to be perfected and developed to the ones we see today. A part of its development was the need to support a lid that covers the treble bridge, treble strings, soundboard, and pins.

After several failed attempts at hinges that were not sturdy enough to support the lid, piano inventors devised the piano hinge that stretched the length of the lid and was capable of supporting its weight.

Shed and Barn Doors

The use of continuous hinges on shed and barn doors is due to their strength, endurance, and longevity because of the constant use of the doors and the inclement conditions. Continuous hinges are stronger than multiple hinges since they run the full length of the door and keep the door from sagging or wavering.

There are specific considerations that have to be examined before placing a continuous hinge on a shed, gate, barn, or carriage house door. The first and most important issues are the weight of the door and its width, followed by the properties and characteristics of the material to which the door will be attached.

Fire Door

Fire door continuous hinges are normally geared continuous hinges, which meet the building codes for fire doors for hospitals, commercial buildings, and hotels and are fabricated with a three hour fire rating. For a hinge to have a three hour fire rating, it must be capable of withstanding combustion during a standard fire test. The hinge must be able to operate efficiently, under intense heat, long enough for occupants of a building to escape.

Detention Prison Doors

Continuous hinges for prisons and detention facilities are designed for heavy use and extreme abuse. The doors for prisons can weigh up to 900 pounds and be four inches thick. In certain cases, continuous hinges for prisons have electrical components that open, close, and lock the door from an observation station. The essential element of all prisons is the door system, which makes correctional institutions highly dependent on the excellent performance of continuous hinges.

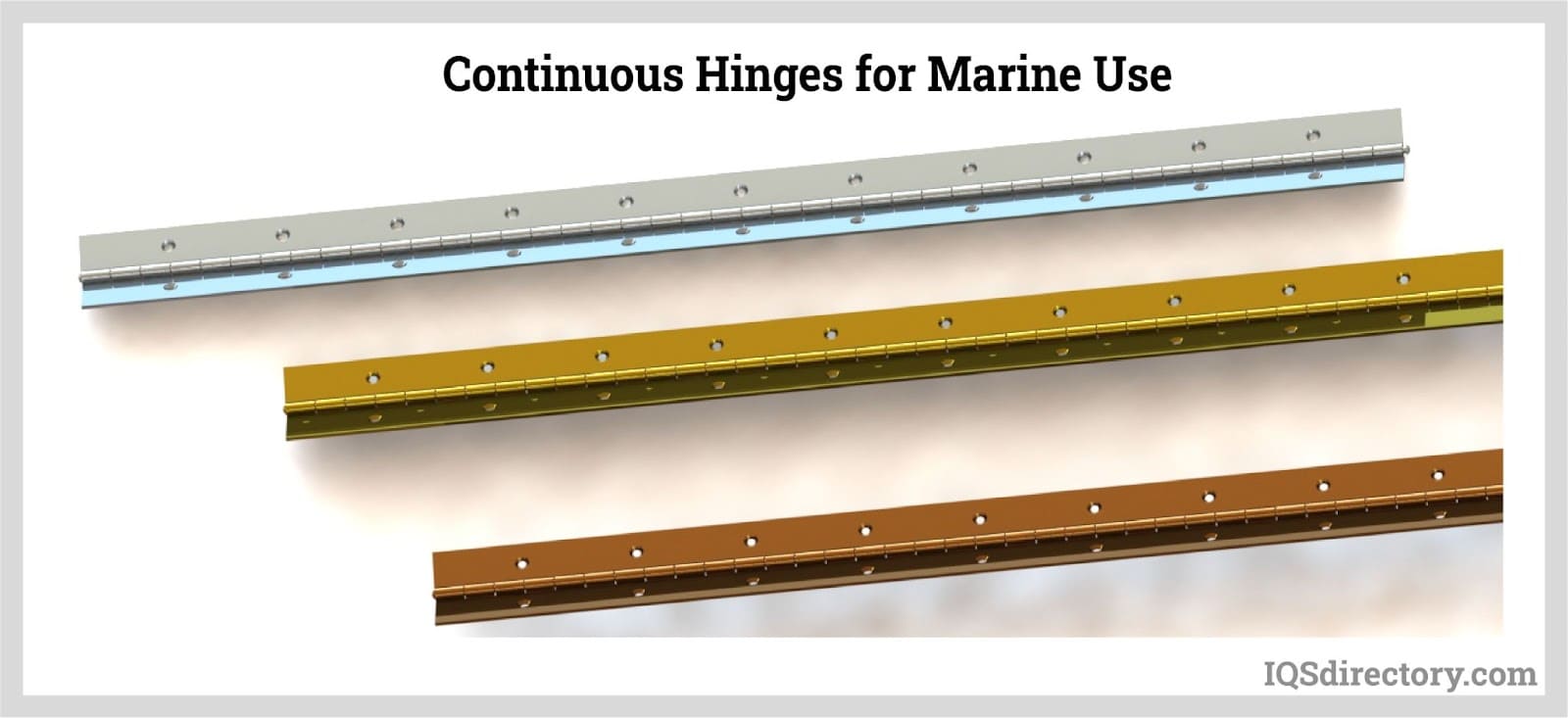

Marine Environments

Though continuous hinges are lightweight, they still offer sufficient stability, strength, resilience, and endurance necessary for use in hostile environments. This is especially necessary for hinges used in marine environments where materials are subjected to salt water that can corrode and rust metals. Rigid full length continuous hinges are used on hatches, doors, and cabinets and are made of various materials, including stainless steel.

Continuous hinges for marine use are coated and waterproofed with a protective oxide layer, making them exceptionally durable and shielded against marine conditions. In certain cases, plastic hinges are used since plastic is unaffected by salt water, oil, chemicals, and solvents.

Desk Top

Though it is possible to use several small hinges to support the top of a desk, continuous hinges offer greater strength and come in styles that are aesthetically pleasing to add to the appearance of a desk. The placement of a hinge on a desktop is a simple and easy process as long as the correct type of hinge is used. The wide variety of continuous hinges makes it possible to select one that exactly fits the weight of the desk top regardless of how heavy it may be.

Chapter Six – Materials Used to Make Continuous Hinges

As simple as continuous hinge construction may be, they are a necessary tool for connecting doors and allowing the doors to smoothly rotate about an axis. There are an endless number of applications where continuous hinges are used. The variety of applications necessitates the use of different materials to meet the requirements of the hinges used.

Common materials used to make hinges include various types of strong and durable metals. Though this is commonly thought of as the ideal continuous hinge material, technological development has led to the introduction of hybrid materials that have many of the characteristics of metals.

Continuous Hinge Materials

Aluminum Continuous Hinges

Aluminum continuous hinges are lightweight, strong, resilient, and corrosion, wear, and rust resistant. One of the reasons for choosing aluminum is its low cost, which is considerably less than stainless steel. Aluminum continuous hinges are half the weight of carbon steel and brass hinges.

Stainless Steel Hinges

Stainless steel continuous hinges are made from a variety of stainless steel series, with 300 series being the most common. Stainless steel series 790 continuous hinges are approved for fire door use by Underwriters Laboratories, Inc. The corrosion resistance of stainless steel continuous hinges makes them ideal for swimming pool buildings, sewage treatment plants, and environments with salt spray.

Copper Continuous Hinges

Copper continuous hinges are used for their aesthetic appearance on cabinets, closets, desks, and other types of cupboard furniture. In most cases, copper is alloyed with other metals to enhance its strength. The color of copper is ideal for creating a decorative and classic appearance. Copper continuous hinges used for desks and cabinets are stronger and more resilient than using several individual copper hinges.

Steel Continuous Hinges

Steel continuous hinges are designed for heavy duty use on doors that weigh over 300 pounds. Plain steel is used for indoor use, while galvanized steel is used for outdoor use. The strength and endurance of steel make an ideal material for continuous hinge manufacturing since steel can endure harsh conditions. The durability of steel makes it the best material for doors that receive constant and stressful use.

The hardness of steel is determined by its carbon content. The higher the carbon content, the harder the steel. In the case of continuous hinges, the choice of hardness increases the number of applications where the hinge can be used. The knuckles on continuous hinges vary according to the size of the door and type of steel, with two inch knuckles being the most common.

Plastic Continuous Hinges

Plastic continuous hinges are an alternative to metal hinges and provide a smooth, quiet, silent, and long lasting operation. Unlike metal hinges with gears and pins, plastic continuous hinges have a flexible joint and are made from a single piece of plastic. For reinforcement and to enhance their strength, plastic hinges may have an increased thickness.

The variations in plastic hinges are determined by the combinations of plastic materials, with certain materials being more resilient. Common types of plastic used for plastic continuous hinges include acrylic, polyvinyl chloride (PVC), polyethylene terephthalate glycol (PETG), and polyolefin. Acrylic, PVC, and PETG are resistant to chemicals and corrosion, while polyolefin is resistant to oil, salt water, solvents, and UV rays.

Carbon Fiber Hinges

Carbon fiber continuous hinges are stronger than metal or plastic hinges and have exceptional strength. The leaves or wings of carbon fiber hinges are made of carbon fiber with an epoxy laminate or hybrid glass. The connecting or flex unit between the wings is Kevlar filled with urethane. The fibers of carbon fiber have exceptional tensile strength with five times the strength of steel and twice the rigidity.

Chapter Seven – The Advantages of Continuous Hinges

Continuous hinges are an essential part of the structure of buildings and provide stability, strength, and resilience to doors, enclosures, and cabinets. For openings that are constantly used and have ongoing stress, continuous hinges have several advantages over the typical three to six inch hinge since continuous hinges provide greater support and have a longer life of usefulness.

One of the main advantages of continuous hinges is keeping an application in proper position without sagging or wavering. Since there isn't any gap between the knuckles and the hinge is one continuous piece, it is very difficult to shift the position of the hinge without applying significant force. This particular feature is the reason that continuous hinges are used in hospitals and as fire doors.

Continuous Hinge Advantages

Position Advantage

Doors with the traditional three to four hinges tend to shift, sag, and lean when they receive a significant amount of abuse. The door configuration tilts and drags during its lifetime of use and loses its smooth operation. A continuous hinged door retains its position during its lifetime of use and does not shift, tilt, or sag. The constancy of a continuous hinge ensures that it will not wear or tear.

Stress Distribution

With a typical hinge configuration, stress is applied to the knuckles and pins of the individual hinges, normally in a three or four hinge configuration. A continuous hinge distributes stress along the length of the door and frame, diffusing wear caused by door kickback shock and eliminating binding.

Operation Benefit

Since much of the resistance of a door is absorbed by the continuous hinge, the door opens with little resistance regardless of the size of the door.

Useful Installation

Continuous hinges for doors or cabinets are attached to the frame and along the complete length of the door or cabinet. This type of connection prevents the door from warping or sagging.

Tight Seal

The full length construction of continuous hinges provides a tight seal to prevent prying, offers complete security, and a tight seal against intrusion. It is for this reason that continuous hinges are used where security and privacy are important.

Easy Customization

Continuous hinges are easily altered to conform to the needs of the application. They can be cut to length and not lose their durability.

Necessary Durability

Smaller hinges have a limited life span due to their size. The dimensions and materials of continuous hinges provide them with the durability necessary to last.

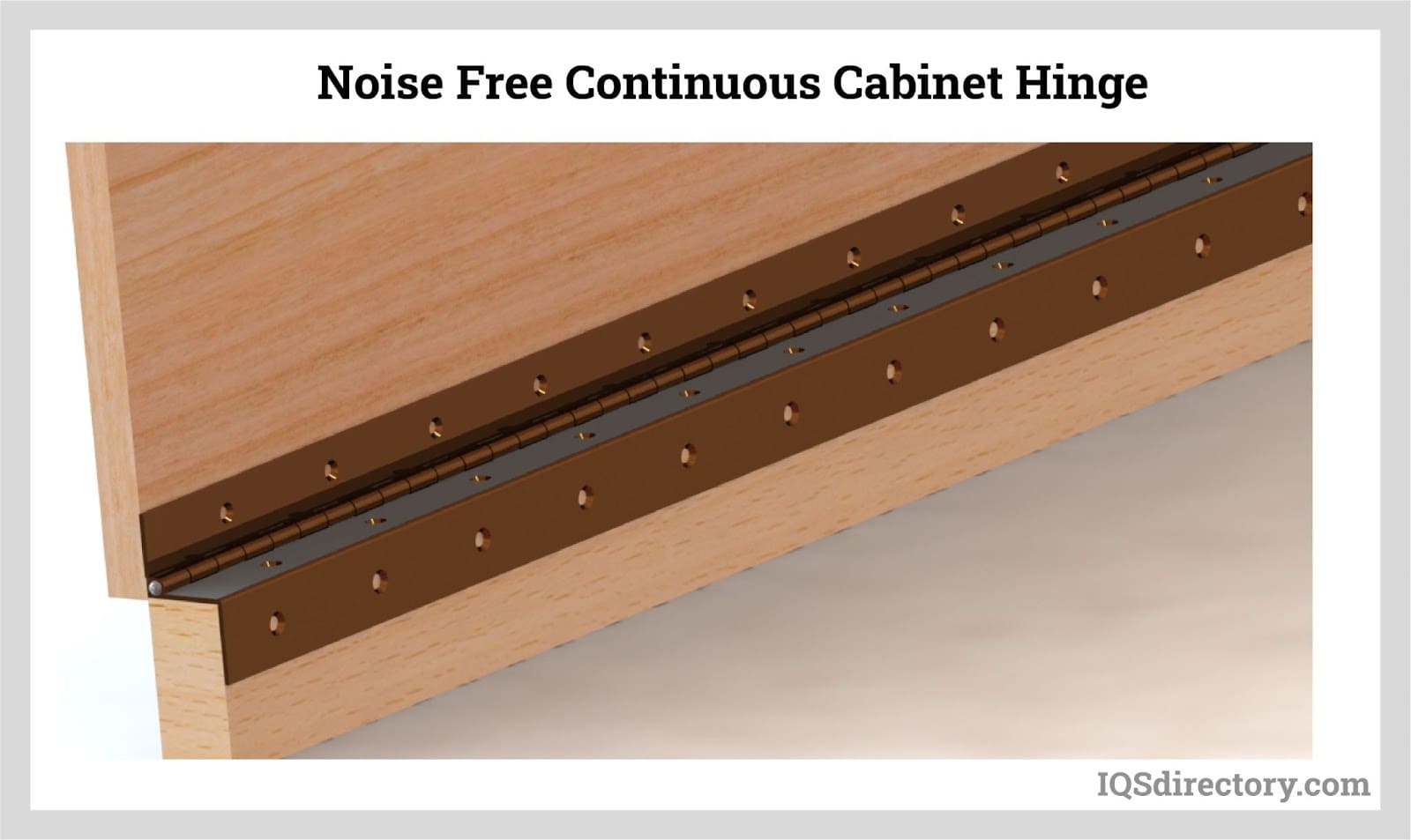

Noise Reduction

This aspect of continuous hinges is the reason that they are used in hospitals and other secure locations where noise can be a problem. Traditional hinges will make crate noise after extended use since they do not have the necessary stress reduction factors. The tight fit of continuous hinges makes them far more secure and less likely to produce noise regardless of the application.

Conclusion

- A continuous hinge is a long single unit hinge that spans the full length of a door, cabinet, lid, or enclosure entrance.

- Over the years, piano hinges have changed and developed into continuous hinges for use in a wide variety of applications and multiple configurations.

- In the varied styles of hinges, continuous hinges stand out due to their length and uncommon usage.

- Unlike the traditional three, four, or five inch hinge found in every home, business, and store, continuous hinges can be six to eight feet long but have a similar structure to that of their smaller cousins.

- Continuous hinges are an essential part of the structure of buildings and provide stability, strength, and resilience to doors, enclosures, and cabinets.

Source: https://www.iqsdirectory.com/articles/hinges/continuous-hinges.html

0 Response to "How Does Ept Continuous Hinge Work"

Post a Comment